High-Quality Continuous Filament Mat for PU Foam Applications

FEATURES & BENEFITS

● Very low binder content

● Low integrity of the layers of the mat

● Low bundle linear density

PRODUCT CHARACTERISTICS

| Product Code | Weight(g) | Max Width(cm) | Solubility in styrene | Bundle density(tex) | Solid content | Resin compatibility | Process |

| CFM981-450 | 450 | 260 | low | 20 | 1.1±0.5 | PU | PU foaming |

| CFM983-450 | 450 | 260 | low | 20 | 2.5±0.5 | PU | PU foaming |

● Other weights available upon request.

● Other widths available upon request.

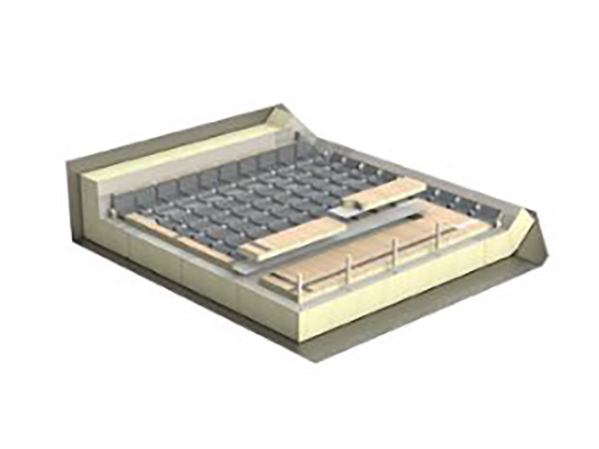

● CFM981 features exceptionally low binder concentration, enabling uniform distribution within the polyurethane matrix throughout the foaming process. This characteristic establishes it as a premium reinforcement solution for insulation applications in liquefied natural gas (LNG) carriers.

PACKAGING

● Inner core options: Available in 3" (76.2mm) or 4" (102mm) diameters with a minimum wall thickness of 3mm, ensuring adequate strength and stability.

● Protective Packaging: Each roll and pallet undergoes individual encapsulation using high-barrier protective film, effectively mitigating risks of physical abrasion, cross-contamination, and humidity ingress throughout transit and warehousing operations. This methodology ensures structural integrity preservation and contamination control, critical for maintaining product quality in demanding logistics environments.

● Labeling & Traceability: Each roll and pallet is labeled with a traceable barcode containing key information such as weight, number of rolls, manufacturing date, and other essential production data for efficient tracking and inventory management.

STORAGING

● Recommended storage conditions: CFM should be kept in a cool, dry warehouse to maintain its integrity and performance characteristics.

● Optimal storage temperature range: 15℃ to 35℃ to prevent material degradation.

● Optimal storage humidity range: 35% to 75% to avoid excessive moisture absorption or dryness that may affect handling and application.

● Pallet stacking: It is recommended to stack pallets in a maximum of 2 layers to prevent deformation or compression damage.

● Pre-use conditioning: Before application, the mat should be conditioned in the worksite environment for at least 24 hours to achieve optimal processing performance.

● Partially used packages: If the contents of a packaging unit are partially consumed, the package should be properly resealed to maintain quality and prevent contamination or moisture absorption before the next usage.